Open Systems

Open Systems

All old procedures to get vinegar were systems, which worked with vinegar mother and the natural air. Most of them are more than 100 years old or a lot older. The oldest system is the natural vinegar, where vinegar mother is on top of the to fermenting liquid.

Natural air comes from outside and the vinegar mother is growing. Vinegar mother are around 10 % vinegar bacteria and the others are slime bacteria. The procedure requires a long time and often the vinegar is not at the wished quality. This system is best for small producers and hobby vinegar makers.

Fetter procedures

The name fetter procedure is coming from the bacteria which are fetted to a natural substance. At the first time, when those systems started the wearing substance was a wooden lattice.

Substance, which are able to wear vinegar bacteria:

Wooden lattice: Those have only a small size and not very much vinegar bacteria do have place on it. Sometimes they are dripping down into the liquid. Through the small surface is only a small air changing possible. Most of the time the wooden lattice was made from beech wood.

Beech wood chips: to get a bigger surface the beech wood was slized and so the producers got bigger surfaces. The cleaning of the chips requires a lot of work. They do not bring any flavor into the vinegar and vinegar bacteria like to sit on it . The fetter substance should not kept longer than one year into the processing vessel to beware of flavor changing. Then the fetter substance should be taken out and refilled. A new vinegar mother is growing within a short time through the bacteria into the liquid.

Submerged vinegar processing

Submerged vinegar processing is the latest development in vinegar processing. Submerged vinegar systems are most commonly used by corporations who produce high quantities of vinegar with a high content of acetic acid. Submerged vinegar processing systems work with the continous aeration of the liquid. The vinegar bacteria are floating in the liquid and do not produce a vinegar mother. Using this system, there is no slime in the machine and the ready vinegar is exceptionally clean and typical. Two systems are used:

Turbine systems: work with a turbine at the bottom of the tank and bring the air into the liquid. Those turbine machines can be controlled automatically with an electronic system: The vinegar is pumped out of the machine when it is ready and is then refilled with wine. These systems are suitable for producers who plan to make more than 50,000 litres of vinegar per year.

Venturi air systems: are smaller and cheaper than turbine systems. The processing is done with a pumping system in a closed stainless steel tank. The air is brought into the liquid with a Venturi air nozzle, which brings air into the pumped liquid. The air bubbles have the same size like the turbine bubbles. The processing time of venturi systems is around 30 % longer than turbine systems, but this is better for quality, because of the lower aeration there is not so much flavour loss. As tastings showed, vinegars from these machines are always better and fruitier.

The changing is done after manual controlling of acetic acid content with a pump or with the pump inside the machine. The refilling is done with an external pump. These machines are very competitive and are available from 20 litres filling up to 600 litres filling. At the moment the venturi air system is the most common processing system for small and medium vinegar makers around the world. Request further information with the contact form.

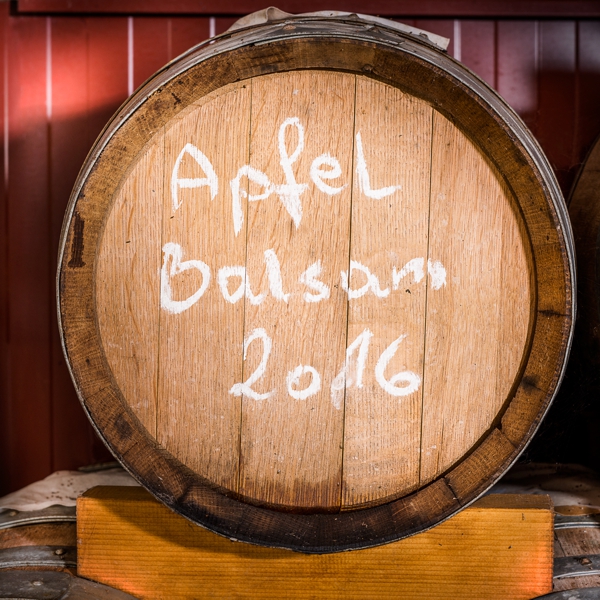

Balsamic vinegar

Balsamic vinegar is said to be the “royal league” of vinegars and it is sometimes sold at very high prices. Traditional balsamic vinegar is a vinegar which is produced during serveral years in an “open fermenting procedure”. The basic product, a grape juice from Trebbiano grapes, is concentrating during the stormy fermentation to at least a third of its primary volume.

This concentrated, thickened storm is then put in the first of five barrels, the oakwood, and stored in a warm area (typically on the attic) for the alcoholic and acetic acid fermentation. As the barrels are permeable to air, the liquid continues to thicken. After approximately one year 2/3 of the vinegar are put into a smaller barrel (most likely chestnut). Following wooden barrels are used in this order: Oak, chestnut, cherry, ash and juniper berry.

A bit of the liquid is left in the barrels as a starting culture for the next procedure. After about 5 years the first balsamic vinegar is ready. The right order of the woods is very important for getting the typical character of this almost black, viscious vinegar. Balsamic vinegar is characterised by its sweet and intensive flavour.